Introduction

80% of water in the world needs treatment, especially in developing countries whatever the ways used for making treatment. Traditionally in rural areas water treatment goes through chlorination but because this way is not effective we currently use chemical water treatment and biological treatment but now VSEP appears as an advanced way in water treatment so let us know what is the difference between them.

Table of Contents

1.1 Traditional Chemical Water Treatment

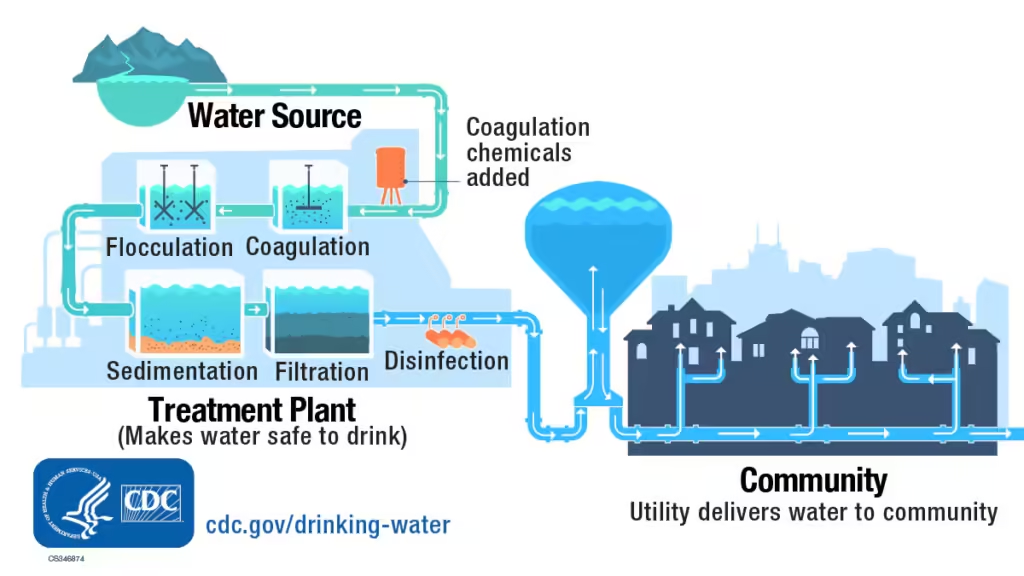

The chemical water treatment method is one of the ways that is commonly used in water treatment that includes many steps that work together starting from coagulation to filtration to give pure water that meets the water quality standards.

1.2 What is the Chemical Water Treatment process?

Firstly, Coagulation

Coagulation is the first step in chemical water treatment that encompasses modifying the electrostatic charges of particles suspended in water, like natural organic matter and solid things.

Secondly, Flocculation

Flocculation and coagulation work together and complete each other with the other meaning after coagulation has clumped the waste particles together, flocculation in water treatment works to remove these clumps.

Thirdly, Sedimentation

Sedimentation is the step in water treatment that moves at a slow speed to settle heavy solid particles at the bottom.

Fourthly, Disinfection

In this step, chlorine is added to water to get rid of all bacteria and inactive microorganisms in water that can cause many diseases and viruses.

Finally, Filtration

Filtration is the final step in chemical water treatment that aims to take water to filter through different materials such as coal, sand, or other granular substances to remove anything that the sedimentation stage left.

2.1 Biological water treatment

In biological water treatment, organic material is used for microbial communities and converted to stable communities that can be separated from water and treated individually so we can take after that pure or clear water that is free of any organic pollution. Biological water treatment depends on the use of bacteria and oxygen to make a successful water treatment process.

Biological Wastewater Treatment by using Bacteria:

The bacteria that can be used in biological water treatment is called anammox (this type of bacterium is used in Nitrogen treatment). This type of bacterium aims to microbial ammonium, to remove ammonia, which is considered one of the largest pollutants in

Wastewater before discharging it.

Oxygen Wastewater Treatment:

This way in water treatment is called (BOD) Biological oxygen Demand, and it depends on determining the amount of oxygen that will be used to make a successful water treatment. BOD can be determined by taking two samples of wastewater. One of them will be dissolved oxygen measured in it and the second one will be saved for five days at 0.2 Celsius before dissolving oxygen is measured in it. The difference between the two samples is BOD.

2.2_ 4 stages to complete biological wastewater treatment:

The primary treatment stage.

Primary treatment stage is a screening stage that aims to remove all organic and inorganic (solids) in water, but after screening is completed, we can not say water is totally pure because it still has minute solids particles so we need the next stage.

Secondary (biological) treatment stage.

About 85% to 90% of organic matter is in the secondary stage by using bacteria in it. In this stage, we can notice that BOD has decreased.

Sterilization:

90% of organic matter is removed in the second stage, but to achieve 100% it can not happen without using Sterilization. Sterilization aims to remove what remains of harmful bacteria. Here are materials that are used in sterilization wastewater:

Chlorine – is added in small amounts to get rid of microorganisms and improve water taste.

Ozone – is used to eliminate colored or any substances that can cause disease.

UV Sterilization – It’s a very effective way to remove any harmful viruses to human life by exposing the water to ultraviolet light for a particular time.

Sludge treatment:

Sludge is the stage that collects an organic mixture of solids suspended in water that can be used as organic fertilizer.

3.1 VSEP Meaning

Vibratory shear-enhanced processing is an advanced method for water treatment and it has excellent results that meet the strict effluent water standards. Application of VESP directly to water can reduce high suspended solids successfully without any chemicals or pretreatment.

Source:

3.2 What is the main idea of VSEP?

The main idea of VSEP technology is vibrating, and this way the VSEP system can treat contaminated streams where conventional technology fails. This is why VSEP water treatment is the best way for water treatment all over the world.

3.3 VSEP Process Explanation

VSEP is a unique separation technology based on vibration to create shear waves of the membrane`s surface that’s what makes VSEP low fouling and on the other hand reduces BOD

3.4 Drive system of VSEP

The structure of VSEP and its vibration dampening for the drive system.

The drive system includes a 10-20 horsepower motor.

3.5 What are the factors that affect the VSEP process?

– Membrane selection – is the most important parameter that affects the water quality of the separation.

– Temperature – in most cases, filtration can be improved through increasing the temperature.

– Vibration amplitude – increased vibration will increase shear wave rate, which directly affects filtration rates.

Conclusion

VSEP has a higher recovery than traditional water treatment ways, plus it saves money and time because VSEP water treatment doesn’t need many processes or steps for complete water treatment processes like chemical water treatment and biological wastewater treatment. VSEP is a single water treatment method where water is treated directly with low fouling and meets water quality standards.