Introduction

Sulfuric acid (H2SO4) is widely used in a wide variety of manufacturing processes. To ensure the quality of the goods these industries produce, it is necessary to measure and determine accurately the concentration of sulfuric acid at all stages of the process. Sulfuric acid was made primarily in Asia and North America and began to be produced on a large scale in the 18th century.

Sulfuric acid is the most important industrial acid, and world production was over 195 million tonnes in 2008. The largest share (roughly 60–70%) is used in the fertilizer industry, although there are numerous other sectors in which sulfuric acid is employed.

Table of Contents

Industries that sulfuric Acid enter in it:

- Explosives

- Drain cleaners

- Synthetic resins

- Insecticides

- Automobile batteries

- Petroleum

- The pickling of metal.

- Antifreeze

- Electroplating

- Pharmaceuticals

- Detergent

- Fertilizers

- Pigments such as paint, enamels, and printing inks

Although the importance of using sulfuric acid in the manufacturing process for different industries, industrial sectors face problems in measuring sulfuric acid safely.

How to determine sulfuric acid content quantitatively ?

Titration

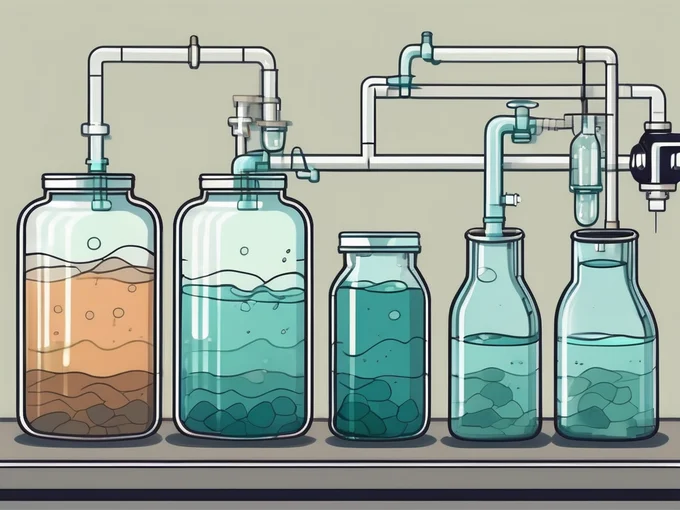

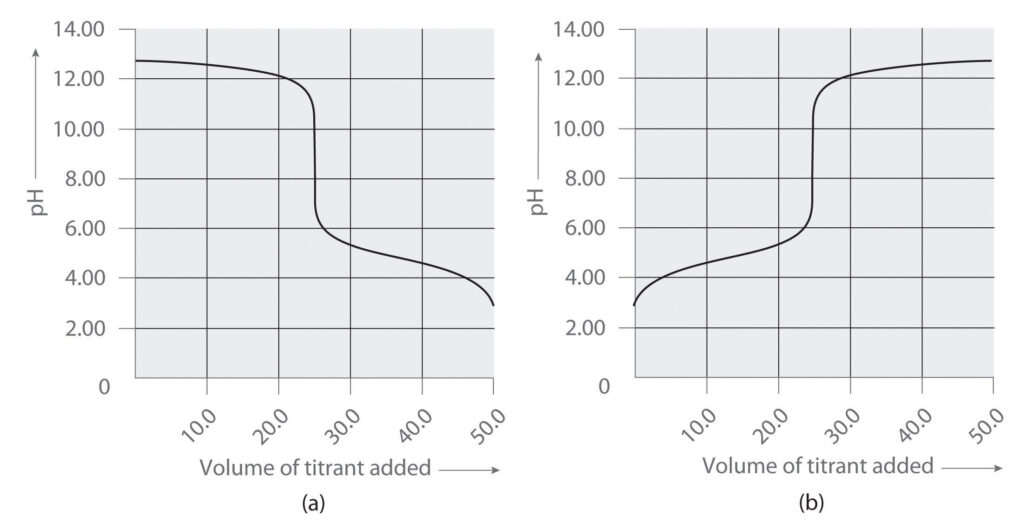

The traditional way of determining or measuring sulfuric-acid is titration. This way required a long time and heavy effort. Additionally, sulfuric-acid’s hygroscopic behavior can lead to changes in concentration over the time taken to complete titration. The longer the titration process, the greater the deviations in concentration could be. Reduced accuracy of concentration measurement would be the result.

Refractometry

The best and easiest solution is refractometry. The measurement is performed by sending a beam of light through a prism in contact with the sample. Depending on the difference in the refractive indices between the sulfuric-acid solution and the prism, the light is partly refracted and reflected, or totally reflected. The critical angle of total reflection is determined by measurement of the reflected light intensity on a CCD array and yields the refractive index.

The refractive index requires only some drops which makes it cost-effective for production or manufacturing processes. Which determines the cost of wasted samples and disposal, as it comes from the measurement option for comparison with repair. Temperature is the factor that most influences refractive agreement measurements. So you will need a device or tool that helps you to follow up the temperature and provides the ability to control it.

Conductivity measurement

One of the most basic solutions to measure sulfuric-acid. Conductivity measurement is a critical parameter used to control process conditions and safeguard process equipment. Despite the cost-effectiveness of electric conductivity, you need to avoid the traditional contracting conductivity sensors because they are so poor and their metal electrodes are corroded by sulfuric acid.

Conclusion

Sulfuric Acid is a critical raw material that needs to be dealt with sensitively whatever is measured or stored because it is highly corrosive and poses potential hazards to both humans and the environment. So you need to determine the right way of storing or measuring. Safe storing will be through choosing the right material but for measuring you can choose one of the following methods: Titration, Refractometry, and Conductivity measurement.

Contact us now if you need a consultation for your industry and you will find a team of experts to rely on you.

Sources

https://manufacturingchemist.com/quick-and-easy-determination-of-sulfuric-acid-content–110585

https://www.gsctanks.com/safety-measures-for-storing-sulfuric-acid-best-practices-and-guidelines