In modern water and wastewater treatment, coagulant dosing is crucial in achieving high water clarity, compliance with regulatory needs, and efficient plant operation. It is no ordinary task of adding chemicals; it requires science and data-based decision-making. One of the most dependable ways of achieving this is the Jar Test, a laboratory test to simulate full-scale coagulation and flocculation processes.

By performing a Jar Test coagulant dose assessment, treatment plant personnel can establish the best coagulant amount needed for current water conditions in order to effectively remove impurities and minimize waste and cost.

What is a Jar Test?

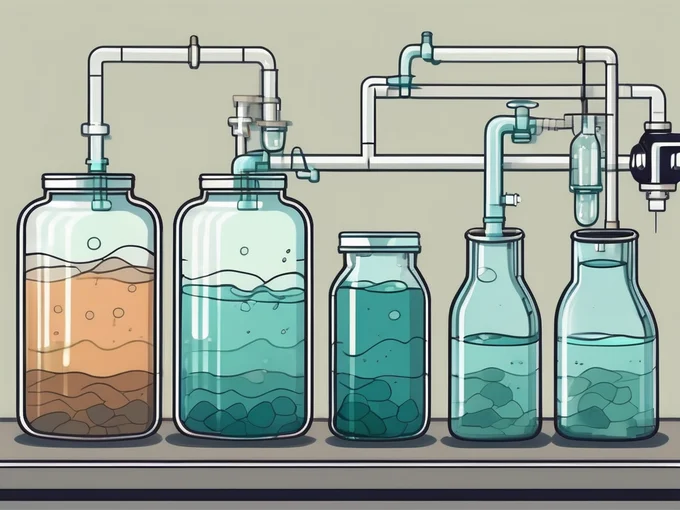

A jar test is a pilot-scale laboratory test that simulates coagulation or flocculation with different doses of chemicals. It is employed to estimate the minimum dose of coagulant required for particular water quality standards. The jar test is employed to determine the appropriate dosage of treatment chemicals, or the minimum dose of chemicals to be applied in order to have an acceptable settling.

Jar testing helps in choosing the proper chemical coagulants and dose to remove suspended impurities and contaminants from water treated in wastewater treatment facilities.

Dosage and type of chemical coagulants are determined from laboratory jar test results, which mimic the conditions of a water treatment plant’s operation.

Lime (calcium hydroxide), alum (aluminum sulfate), and iron salts (ferric or ferrous) are the most widely used coagulants.

Flocculation or coagulation is the cornerstone in any water treatment system, and it is a propaedeutic process for sedimentation, filtration, and disinfection before water distribution for domestic and industrial use.

Jar Test Process for Coagulant Dosing

Using a flocculator, the coagulant material is added to the beakers containing the water sample. The chemical coagulant starts precipitating, trapping all the impurities and developing flocs that will settle at the bottom of the beaker.

The sample is agitated throughout to enable the development, expansion, and settling of floc to occur as it would in a large-plant unit and be observable to see.

The operator then performs a series of tests to assess the impact of different levels of flocculation agents at different pH levels to determine the correct size floc.

The most common analytical conditions with a flocculator are:

-1,000 mL glass beakers (jars), tall form, Ø 105 mm.

-600 mL wastewater samples and coagulants.

-Paddles in the middle height of the sample.

-Turbulent stirring at 120 rpm for 120 seconds.

-Slow-speed flocculation at 30 rpm for 25 minutes.

-Initial assessment of results after 5 minutes of sedimentation.

Results Evaluation for Optimizing Performance

Results Evaluation for Optimizing Performance, The performance of a jar test can be evaluated on different bases:

-Assessment of floc size with numerical degree.

-Time between chemical addition and first floc appearance.

-Remainder turbidity of the supernatant following a predetermined sedimentation time measurement by turbidimeter.

-Electrokinetic potential of suspended particle measurement on an immediately obtained sample after chemical addition and mixing.

-Clarified water filterability determination by pressure-filtration through standardized membrane filters (the fall of water flow is related to fouled filters and residual unsettled suspended matter).

Factors Affecting Jar Test Results

In general, two distinct chemicals are employed while conducting a jar test. Based on the wastewater employed in the test, even the pH of the wastewater may have to be conditioned. The addition sequence of the chemicals is important.

pH Adjust—Sometimes flocculants and coagulants will not work at a specific pH. Sometimes an oily waste stream requires what we call an “acid crack.” This is where you acid crack the pH of the oily water, and the oils are drained from the water. This makes treatment much easier. After acid cracking, you can reset the pH to a desired spot using a caustic soda or base.

And other characteristics of the wastewater, such as the type and concentration of particles and other chemicals, can also have a dramatic impact on the performance of the coagulant and flocculant. The quantity and type of coagulant and flocculant used can also have a significant impact on the end result. Too much or too little of these chemicals can lead to ineffective treatment.

Conclusion

The Jar Test is a very useful tool in optimizing wastewater treatment. It allows comparisons to be made between a range of different treatments simultaneously, providing useful information on the optimum method of treatment. It is, however, imperative that its limitation be taken into account and that the treatment conditions be modulated as needed from the operation of the full-scale plant.

It is also vital to take into account the economic expense and environmental impact of the flocculant and coagulant chemicals. While such chemicals are needed for effective treatment, they can be expensive and harmful to the environment. Thus, careful utilization of these chemicals is essential, and other treatment options should be sought out wherever possible.